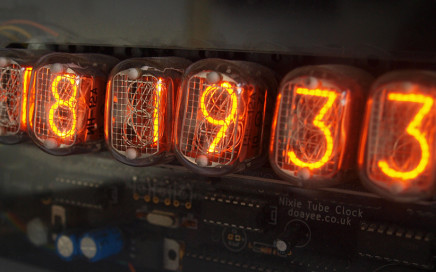

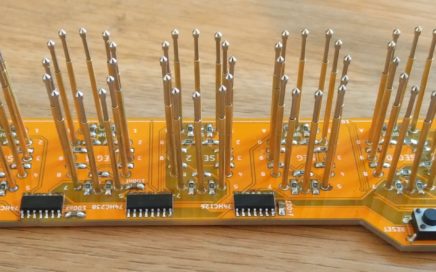

Nixie Tube Driver Test Jig

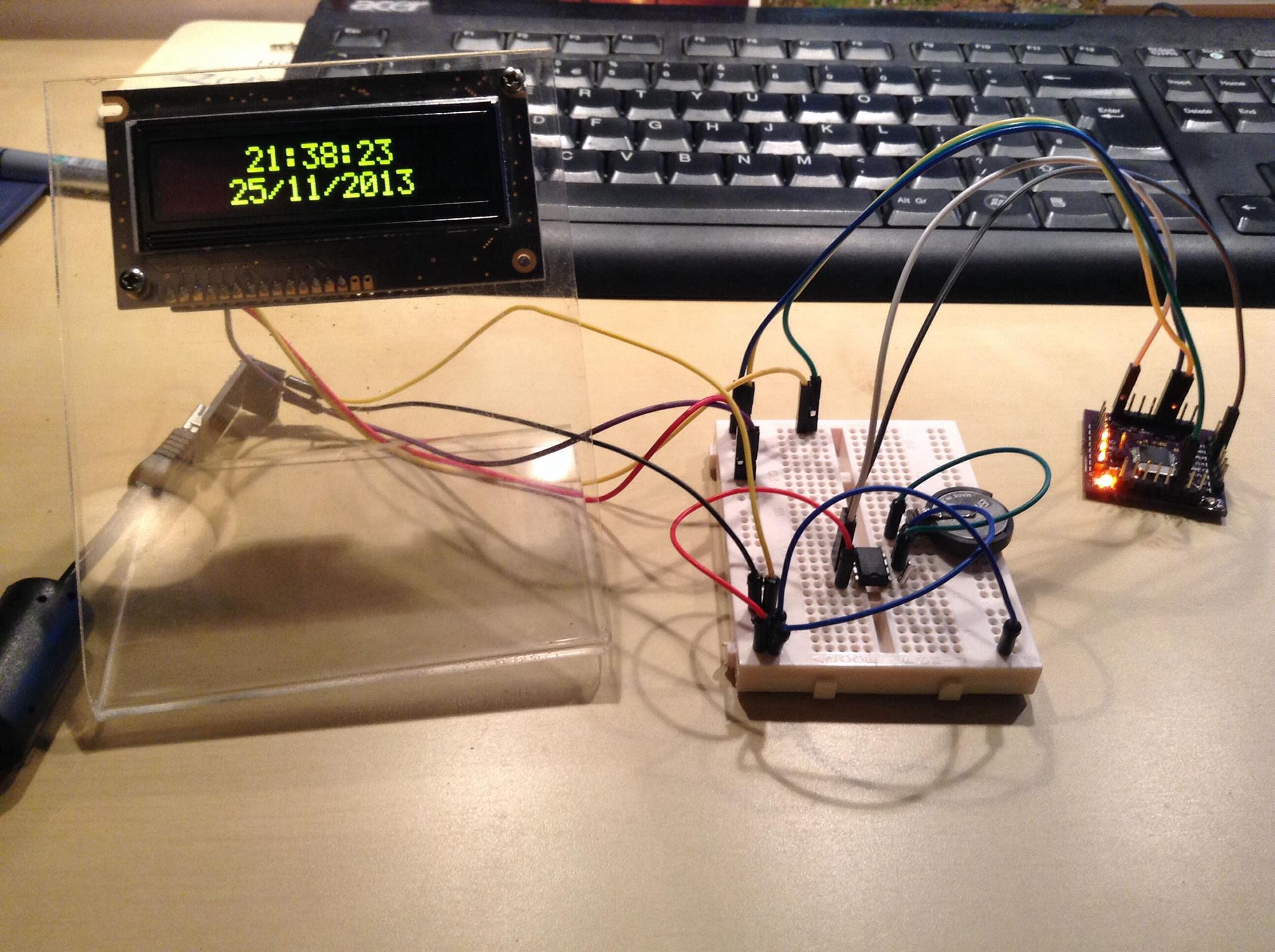

For those of you who don’t already know, recently we ran a Kickstarter for our Nixie Tube Driver (NTD). The project was a huge success. To follow on from that, we ordered a second batch of drivers to put on our tindie store. The difference this time, however, is that we weren’t building these drivers […]